The Ideal Workshop Layout For 2025: A Comprehensive Guide

The Ideal Workshop Layout for 2025: A Comprehensive Guide

Related Articles: The Ideal Workshop Layout for 2025: A Comprehensive Guide

- COVID-19 Research Topic Ideas For 2025: Exploring The Next Frontier

- 2 Truths And A Lie Ideas Reddit 2025: The Ultimate Guide To Crafting Intriguing And Mind-Boggling Statements

- Halloween Witch Face Makeup Ideas 2025: Enchanting Transformations For The Spooky Season

- Halloween Witch Makeup Ideas 2025: Bewitching Looks To Cast A Spell

- Cheap And Easy Dinner Ideas For Kids In 2025

Introduction

With great pleasure, we will explore the intriguing topic related to The Ideal Workshop Layout for 2025: A Comprehensive Guide. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Video about The Ideal Workshop Layout for 2025: A Comprehensive Guide

The Ideal Workshop Layout for 2025: A Comprehensive Guide

Introduction

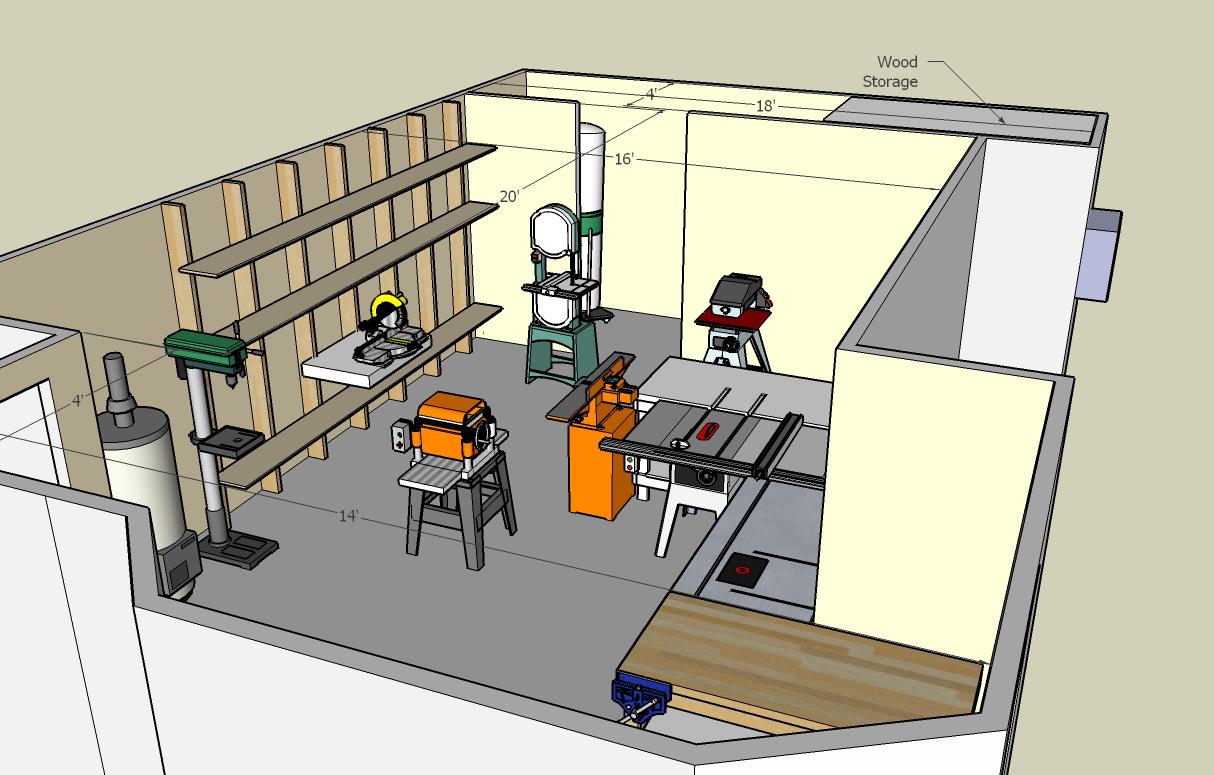

In the rapidly evolving manufacturing landscape, optimizing workshop layout is crucial for maximizing efficiency, productivity, and competitiveness. As we approach 2025, technological advancements and industry best practices are shaping the ideal workshop layout, transforming it into a hub of innovation and operational excellence. This comprehensive guide will delve into the key considerations, design principles, and innovative solutions that define the ideal workshop layout for the future.

Key Considerations for the Ideal Workshop Layout

- Flexibility and Adaptability: Workshops must be designed to accommodate changing production demands, new technologies, and evolving market trends. Flexible layouts allow for quick reconfigurations and expansions, ensuring responsiveness to market dynamics.

- Efficient Material Flow: Optimized material flow minimizes handling times and reduces production delays. The layout should facilitate seamless movement of materials from receiving to production and finished goods storage.

- Ergonomics and Safety: A well-designed workshop promotes employee well-being and safety. Ergonomic workstations, proper ventilation, and clear walkways prevent musculoskeletal disorders and accidents.

- Technology Integration: Advanced technologies such as automation, robotics, and digital twinning are reshaping workshop operations. The layout should incorporate these technologies seamlessly to enhance productivity and quality.

- Sustainability: Environmental consciousness is becoming increasingly important. Energy-efficient lighting, renewable energy sources, and waste reduction measures should be incorporated into the workshop design.

Design Principles for the Ideal Workshop Layout

- Cellular Manufacturing: This layout groups similar machines and processes into cells, creating focused production areas that improve efficiency and reduce bottlenecks.

- Lean Principles: The principles of lean manufacturing, such as value stream mapping and continuous improvement, guide the design of efficient and waste-free layouts.

- Modular Design: Modular components and standardized equipment allow for easy expansion and reconfiguration, adapting the layout to changing production needs.

- Vertical Integration: Utilizing vertical space through multi-level platforms and mezzanines maximizes floor space and improves material flow.

- Integrated Logistics: The layout should incorporate automated material handling systems, such as conveyors and automated guided vehicles (AGVs), to streamline material movement.

Innovative Solutions for the Ideal Workshop Layout

- Automated Storage and Retrieval Systems (AS/RS): These systems optimize space utilization and improve material handling efficiency by storing and retrieving materials automatically.

- Robotic Process Automation (RPA): Robots can perform repetitive tasks, such as assembly and packaging, freeing up human workers for more complex operations.

- Digital Twin Technology: Digital replicas of the workshop enable virtual simulations and optimization of layout and processes before physical implementation.

- Real-Time Data Analytics: Sensors and IoT devices collect data on equipment performance, material flow, and other metrics, providing insights for continuous improvement.

- Predictive Maintenance: Advanced algorithms analyze data to predict equipment failures, enabling proactive maintenance and minimizing downtime.

Benefits of the Ideal Workshop Layout

- Increased Productivity: Optimized layouts minimize waste and streamline operations, resulting in significant productivity gains.

- Improved Quality: Efficient material flow and ergonomic workstations reduce errors and enhance product quality.

- Reduced Costs: Optimized layouts minimize handling costs, energy consumption, and maintenance expenses.

- Enhanced Flexibility: Flexible layouts enable rapid response to changing market demands and new product introductions.

- Improved Safety and Ergonomics: Well-designed layouts promote employee well-being and reduce the risk of accidents.

Conclusion

The ideal workshop layout for 2025 is a dynamic and innovative space that combines flexibility, efficiency, technology, and sustainability. By embracing these key considerations, design principles, and innovative solutions, manufacturers can create workshops that drive operational excellence, maximize productivity, and position their businesses for success in the years to come. As the industry continues to evolve, the ideal workshop layout will remain a cornerstone of manufacturing competitiveness, enabling companies to adapt, innovate, and thrive in a rapidly changing global market.

![[IMGSRCTITLE2]](http://www.workshopshed.com/wp-content/uploads/2017/10/Workshop3.jpg)

![[IMGSRCTITLE3]](https://i.ytimg.com/vi/lTGxbnLRX1Y/maxresdefault.jpg)

![[IMGSRCTITLE4]](https://i.pinimg.com/originals/46/d0/04/46d004c690adfbfe1a505501740feec7.jpg)

![[IMGTITLE5]](https://i.pinimg.com/originals/df/b1/f6/dfb1f6a18a236f39e2634401da7fe549.jpg)

![[IMGTITLE6]](https://cdn.jhmrad.com/wp-content/uploads/project-carpentry-workshop-floor-plan-learn_62137.jpg)

![[IMGTITLE7]](https://i.pinimg.com/474x/dc/9b/2b/dc9b2b907e159b58545d882481927897--workshop-plans-workshop-layout.jpg)

![[IMGTITLE8]](https://i.pinimg.com/originals/cb/cb/0b/cbcb0bca0adfd6cfd41c639282db7585.jpg)

![[IMGTITLE9]](https://www.iforgeiron.com/uploads/monthly_2017_05/Workshop_Layout.jpg.6f2777d83cff69c6f828f45d3bcb3514.jpg)

Closure

Thus, we hope this article has provided valuable insights into The Ideal Workshop Layout for 2025: A Comprehensive Guide. We appreciate your attention to our article. See you in our next article!

![[IMGSRCTITLE2]](https://www.decorationlove.com/wp-content/uploads/2016/09/Spa-Look-Bathroom-Ideas.jpg)

![[IMGSRCTITLE3]](https://i.pinimg.com/originals/30/fb/d2/30fbd270c74ebff57e293616b6612f27.jpg)

![[IMGSRCTITLE4]](https://i.pinimg.com/originals/2f/30/2c/2f302c23e3aea6979d50a449dcc25b18.jpg)

![[IMGTITLE5]](https://uploads-ssl.webflow.com/6296aec5884dc4c8a90970a6/62d9b5b769c49a57de5ca495_Copy%20of%20%40shophousedesign.jpg)

![[IMGTITLE6]](https://i.pinimg.com/originals/db/3c/82/db3c8233fb6d9166e6cb20debcc2ac52.jpg)

![[IMGTITLE7]](https://uploads-ssl.webflow.com/6296aec5884dc4c8a90970a6/62d9b9e449788b34b32c1761_Copy%20of%20%40kpid-counterpoint-barbara-barry-faucet.jpg)

![[IMGTITLE8]](https://decoholic.org/wp-content/uploads/2015/04/spa-style-bathroom-3.jpg)

![[IMGTITLE9]](https://i1.wp.com/magzhouse.com/wp-content/uploads/2019/08/Fabulous-Modern-Master-Bathroom-Design-Ideas-18.jpg)

![[IMGSRCTITLE2]](https://cdn.cdnparenting.com/articles/2021/03/30184332/1397230445.jpg)

![[IMGSRCTITLE3]](https://www.weareteachers.com/wp-content/uploads/invention-ideas-for-kids.png)

![[IMGSRCTITLE4]](https://cdn2.momjunction.com/wp-content/uploads/2021/12/10-Simple-Yet-Cool-Invention-Ideas-For-Kids-624x702.jpg)

![[IMGTITLE5]](https://babytoyszoo.com/wp-content/uploads/2022/08/babytoyszoo.com_.png)

![[IMGTITLE6]](https://www.liveenhanced.com/wp-content/uploads/2018/06/new-technology-inventions-for-the-future-20.jpg)

![[IMGTITLE7]](https://i.ytimg.com/vi/Xl8WNZeFkPc/maxresdefault.jpg)

![[IMGTITLE8]](https://inventiontherapy.com/wp-content/uploads/2019/12/kid-inventions-600x337.png)

![[IMGTITLE9]](https://www.uniqueideas.site/wp-content/uploads/crazy-kids-inventions-turned-into-real-products-15-pics-bored-panda-7.jpg)

![[IMGSRCTITLE2]](https://www.elmens.com/wp-content/uploads/2021/01/Benefits-Of-Learning-A-New-Language-1920x1240.jpg)

![[IMGSRCTITLE3]](https://www.getblend.com/wp-content/uploads/2021/06/Future-of-English-Language.jpg)

![[IMGSRCTITLE4]](https://ncee.org/wp-content/uploads/2020/06/Future-Learning.png)

![[IMGTITLE5]](https://image.slidesharecdn.com/britishcouncillanguagelearningforthefuture-170311125518/95/language-learning-for-the-future-1-638.jpg?cb=1489236942)

![[IMGTITLE6]](https://www.britishcouncil.org/sites/default/files/solas_image.png)

![[IMGTITLE7]](https://oxfordhousebcn.com/wp-content/uploads/artificial-intelligence-870jpg.jpg)

![[IMGTITLE8]](https://onpassive.com/blog/wp-content/uploads/2020/03/Natural-Language-Processing.jpg)

![[IMGTITLE9]](https://www.teachingenglish.org.uk/sites/teacheng/files/images/Future_Learning_RS8507_GettyImages-597273573-hig.jpg)

![[IMGSRCTITLE2]](https://i.ytimg.com/vi/zl-uX9Hhlys/maxresdefault.jpg)

![[IMGSRCTITLE3]](http://s892816813.onlinehome.us/aifawards.com/images/catalogCover.jpg)

![[IMGSRCTITLE4]](https://i.pinimg.com/originals/23/0e/dc/230edc5b50aa8861a06b3cfd7b4249c6.png)

![[IMGTITLE5]](https://www.fabshapes.com/wp-content/uploads/2020/04/Acrylic-plastic-fabrication-1024x683.jpg)

![[IMGTITLE6]](https://image.isu.pub/120216220121-8cd6369221594d81b6de1b9a5a718ade/jpg/page_1.jpg)

![[IMGTITLE7]](https://i.ytimg.com/vi/tGoCWeSHz4M/maxresdefault.jpg)

![[IMGTITLE8]](https://images.crunchbase.com/image/upload/c_lpad,h_256,w_256,f_auto,q_auto:eco,dpr_1/tku1qt6ceekbovrsvdw8)

![[IMGTITLE9]](https://media.glassdoor.com/sqll/2514203/acrylic-idea-factory-squarelogo-1552872919912.png)

![[IMGSRCTITLE2]](https://thumbs.dreamstime.com/b/new-year-black-dotted-lines-white-background-vector-illustration-239189610.jpg)

![[IMGSRCTITLE3]](https://thumbs.dreamstime.com/b/new-year-white-dotted-lines-black-background-vector-illustration-237644404.jpg)

![[IMGSRCTITLE4]](https://png.pngtree.com/png-vector/20240115/ourlarge/pngtree-black-and-white-2025-years-vector-png-image_11441626.png)

![[IMGTITLE5]](https://img.freepik.com/premium-vector/happy-new-year-2025-with-black-white-concept-with-touch-simple-light-effects_533730-2071.jpg)

![[IMGTITLE6]](https://static.vecteezy.com/system/resources/previews/005/145/050/large_2x/happy-new-year-2025-t-shirt-design-vector.jpg)

![[IMGTITLE7]](https://www.shutterstock.com/image-vector/numbers-2025-black-on-white-260nw-2246465435.jpg)

![[IMGTITLE8]](https://i.etsystatic.com/22685588/r/il/537377/3075521524/il_fullxfull.3075521524_nk7s.jpg)

![[IMGTITLE9]](https://i.etsystatic.com/22332676/r/il/009e47/3305577071/il_1080xN.3305577071_p1z5.jpg)

![[IMGSRCTITLE2]](https://dinnerthendessert.com/wp-content/uploads/2020/06/Oven-Baked-Rotisserie-Chicken-Breasts-3-1024x1536.jpg)

![[IMGSRCTITLE3]](https://www.recipetineats.com/wp-content/uploads/2018/09/Honey-Garlic-Chicken-Breast_5.jpg)

![[IMGSRCTITLE4]](https://www.primaverakitchen.com/wp-content/uploads/2019/03/Garlic-Butter-Baked-Chicken-Breast-Primavera-Kitchen-2.jpg)

![[IMGTITLE5]](https://cafedelites.com/wp-content/uploads/2018/12/Creamy-Garlic-Chicken-Breasts-IMAGE-55.jpg)

![[IMGTITLE6]](https://1.bp.blogspot.com/-5JUNfmcRaZU/XwsH3cHNWCI/AAAAAAAABDU/_1Wz-CnT7LY8wqkfmWQWjSYoYOQnKQN-ACLcBGAsYHQ/s1800/Baked-Chicken-Breast-Primavera-Kitchen-11.jpg)

![[IMGTITLE7]](https://www.cookingclassy.com/wp-content/uploads/2019/03/baked-chicken-breast-10.jpg)

![[IMGTITLE8]](https://www.eatwell101.com/wp-content/uploads/2021/06/Creamy-Garlic-Chicken-Breasts-with-Crispy-Bacon-reicpe.jpg)

![[IMGTITLE9]](https://www.gimmesomeoven.com/wp-content/uploads/2015/05/Oven-Baked-Chicken-Breast-Recipe-4-1-768x1152.jpg)

![[IMGSRCTITLE2]](https://i.ytimg.com/vi/dittbKJkshM/maxresdefault.jpg)

![[IMGSRCTITLE3]](https://www.franchisemarket.ph/application/files/8716/0690/5718/small-business-ideas.jpg)

![[IMGSRCTITLE4]](https://i.ytimg.com/vi/pYTUvfttf0E/maxresdefault.jpg)

![[IMGTITLE5]](https://lisasharpcreative.com/wp-content/uploads/2019/12/small-business-ideas-pin-1.jpg)

![[IMGTITLE6]](https://i.pinimg.com/originals/0a/99/49/0a9949a834244a378a5ac5a8c90793a4.jpg)

![[IMGTITLE7]](https://i.ytimg.com/vi/hcA9J_r0EJg/maxresdefault.jpg)

![[IMGTITLE8]](https://www.fincyte.com/wp-content/uploads/2019/11/Best-Small-Business-Ideas-in-the-Philippines.jpg)

![[IMGTITLE9]](https://www.thecuriousfrugal.com/wp-content/uploads/2021/01/Small-business-ideas-from-home-1.jpg)

![[IMGSRCTITLE2]](http://fordiyers.com/wp-content/uploads/2017/10/Raised-Bed-With-Benches.jpg)

![[IMGSRCTITLE3]](https://i.pinimg.com/originals/b3/15/55/b31555053bcdde00b3a87359f3a9dced.jpg)

![[IMGSRCTITLE4]](https://www.apieceofrainbow.com/wp-content/uploads/2019/01/diy-raised-bed-gardens-ideas-designs-build-garden-boxes-planters-elevated-beds-wood-pallets-cinder-block-flowers-vegetable-gardening-apieceofrainbow-18-768x1229.jpg)

![[IMGTITLE5]](https://www.apieceofrainbow.com/wp-content/uploads/2019/01/diy-raised-bed-gardens-ideas-designs-build-garden-boxes-planters-elevated-beds-wood-pallets-cinder-block-flowers-vegetable-gardening-apieceofrainbow-21.jpg)

![[IMGTITLE6]](http://fordiyers.com/wp-content/uploads/2017/10/Pallet-Garden-Beds-768x574.jpg)

![[IMGTITLE7]](https://freshpatio.com/wp-content/uploads/2022/10/raised-garden-bed-idea-by-thishouseofdreams.jpeg)

![[IMGTITLE8]](https://freshpatio.com/wp-content/uploads/2022/10/plastic-crates-raised-garden-bed-idea.jpg)

![[IMGTITLE9]](https://www.apieceofrainbow.com/wp-content/uploads/2019/01/diy-raised-bed-gardens-ideas-designs-build-garden-boxes-planters-elevated-beds-wood-pallets-cinder-block-flowers-vegetable-gardening-apieceofrainbow-11-768x1366.jpg)

![[IMGSRCTITLE2]](https://i.pinimg.com/originals/1a/53/53/1a5353d7581a62df0aae6dc0a404bbab.jpg)

![[IMGSRCTITLE3]](https://i.pinimg.com/originals/03/82/a6/0382a631f429775be34506247143cb1a.jpg)

![[IMGSRCTITLE4]](https://i.etsystatic.com/22177419/r/il/f2c328/2891612578/il_fullxfull.2891612578_8nmv.jpg)

![[IMGTITLE5]](https://www.passingdownthelove.com/wp-content/uploads/2018/09/80th-birthday-gifts-pin2.jpg)

![[IMGTITLE6]](https://www.chatterboxwalls.co.uk/images/examples/80th-birthday-gift-for-him-custom-frame.jpg)

![[IMGTITLE7]](https://giftlab.co/wp-content/uploads/2021/01/card.jpg)

![[IMGTITLE8]](https://www.loveandlavender.com/wp-content/uploads/2022/04/theultimategiftguidefor80thbirthday.jpg)

![[IMGTITLE9]](https://www.abcflor.com/wp-content/uploads/Rhinestones-80th-Birthday-Keepsake-Souvenir.jpg)